Finishing:

Creative freestyle fortangible prints

The perfect polish in order to make printed matter into sought-after valuables

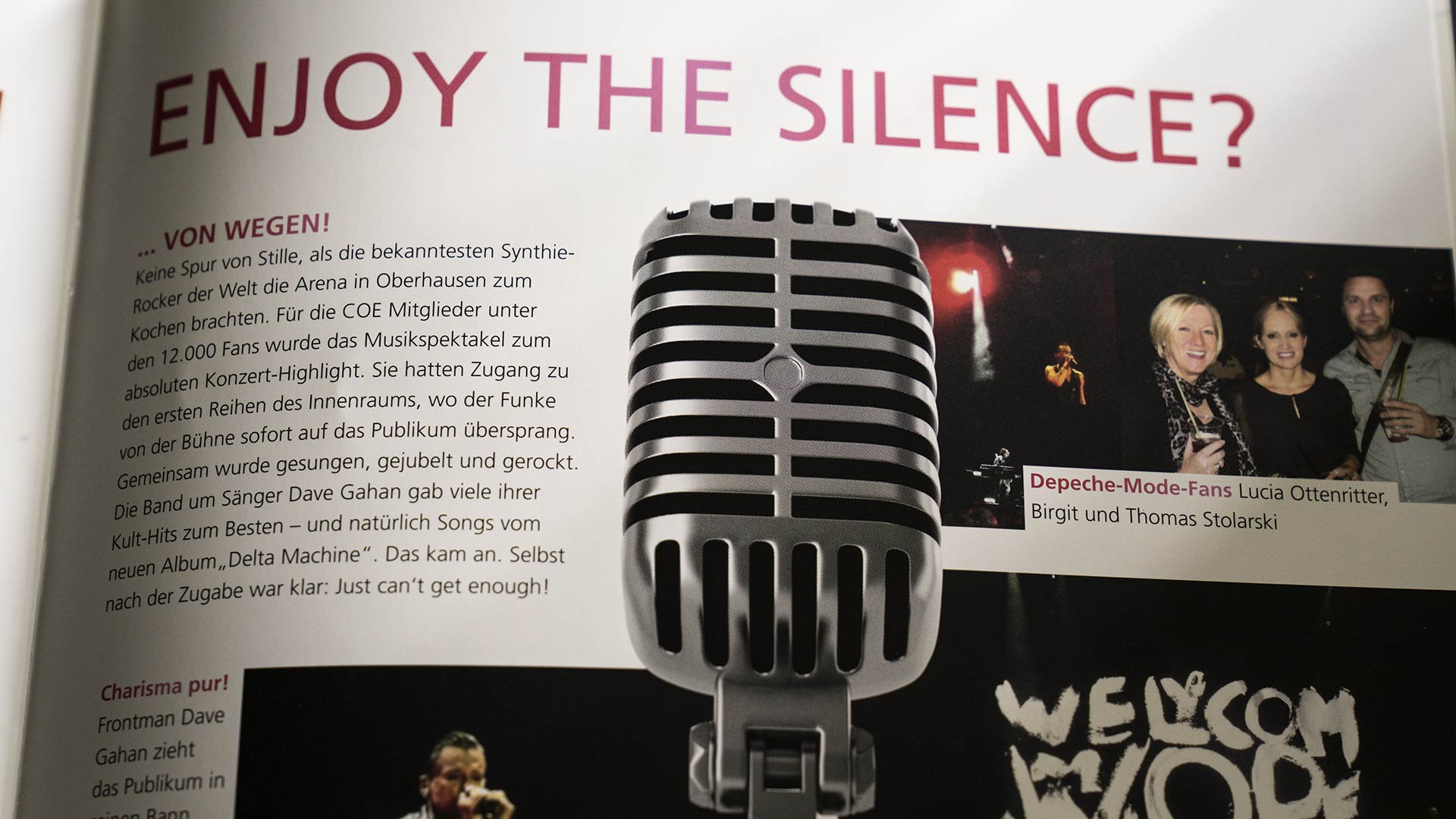

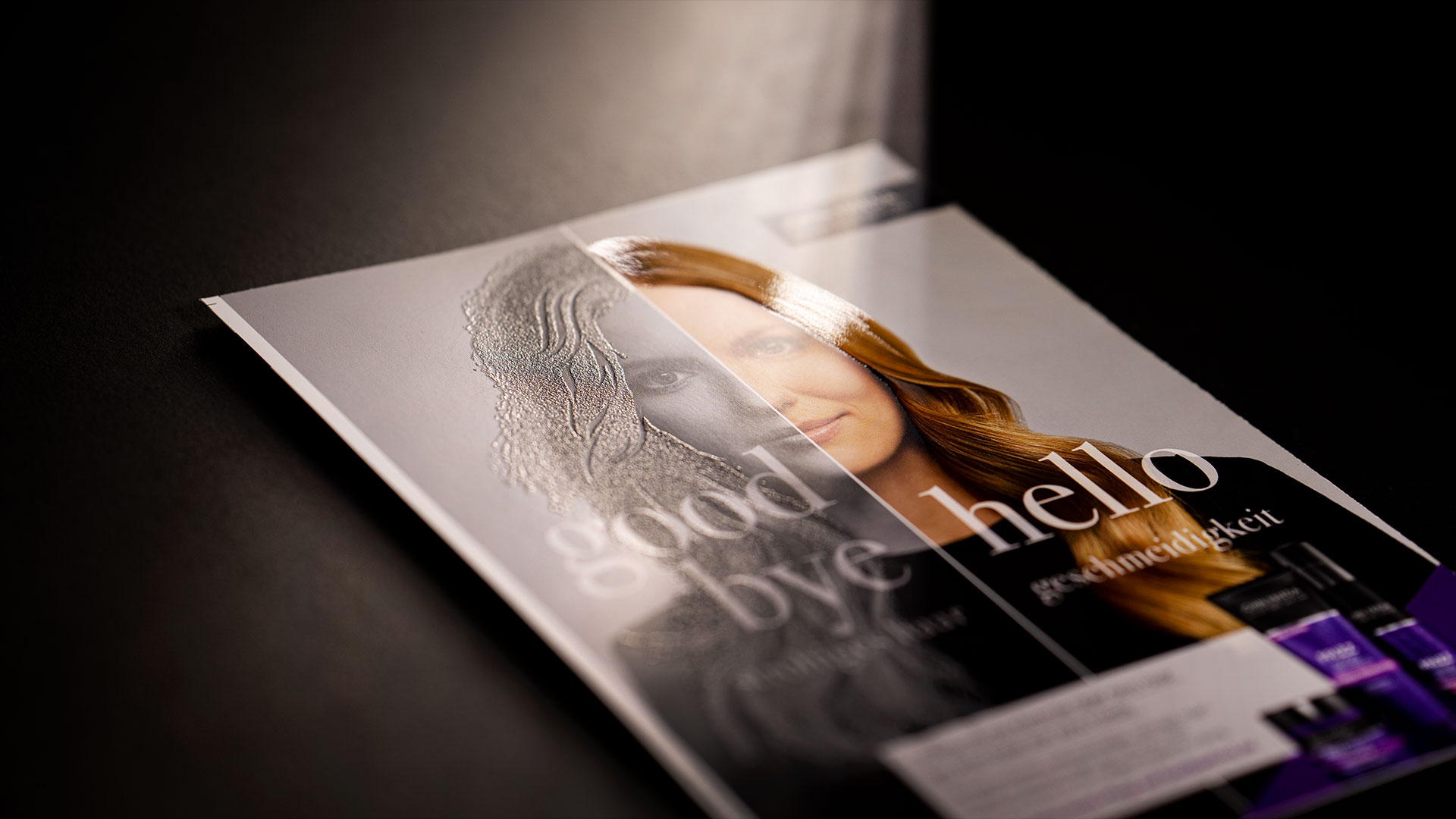

Print finishings transform printed products into experiences that appear true-to-nature. They make mailshots, envelopes, postcards and stickers shimmer, sparkle, give off lovely scents and gleam. Matt/gloss contrasts increase the sophistication of envelopes, brochures or ad specials. Lettering, lines and motifs become haptic and appear in three dimensions. Fascinatingly genuine-looking nacreous lustre effects, changing, iridescent, brilliantly shiny or elegantly frosted advertising media and printed matter catch the eye, emotionalise and generate a high level of sophistication.

Print finishings may protect products from yellowing, make print products scratch-free and abrasion-resistant, and enable them to withstand external influences. Foil laminations may increase the life expectancy and individual character of printed products 1,500-fold, ensure an optical appearance that is as smooth as glass or that resembles frosted glass and that can be perfectly combined with various screen print finishings.

Inline finishing

using special colours

Corporate Identity-compliant: Have your corporate colours reproduced with precision

With special colours, such as HKS colours, or letter paper refined using Pantone colours, business cards, annual reports or image brochures, we secure the exact colour reproduction of your logos and your corporate design elements - print run by print run.

A piece of advice from B&K’s finishing specialists: Special colour printing is very well suited for finishing (varnishing, embossing, lamination)

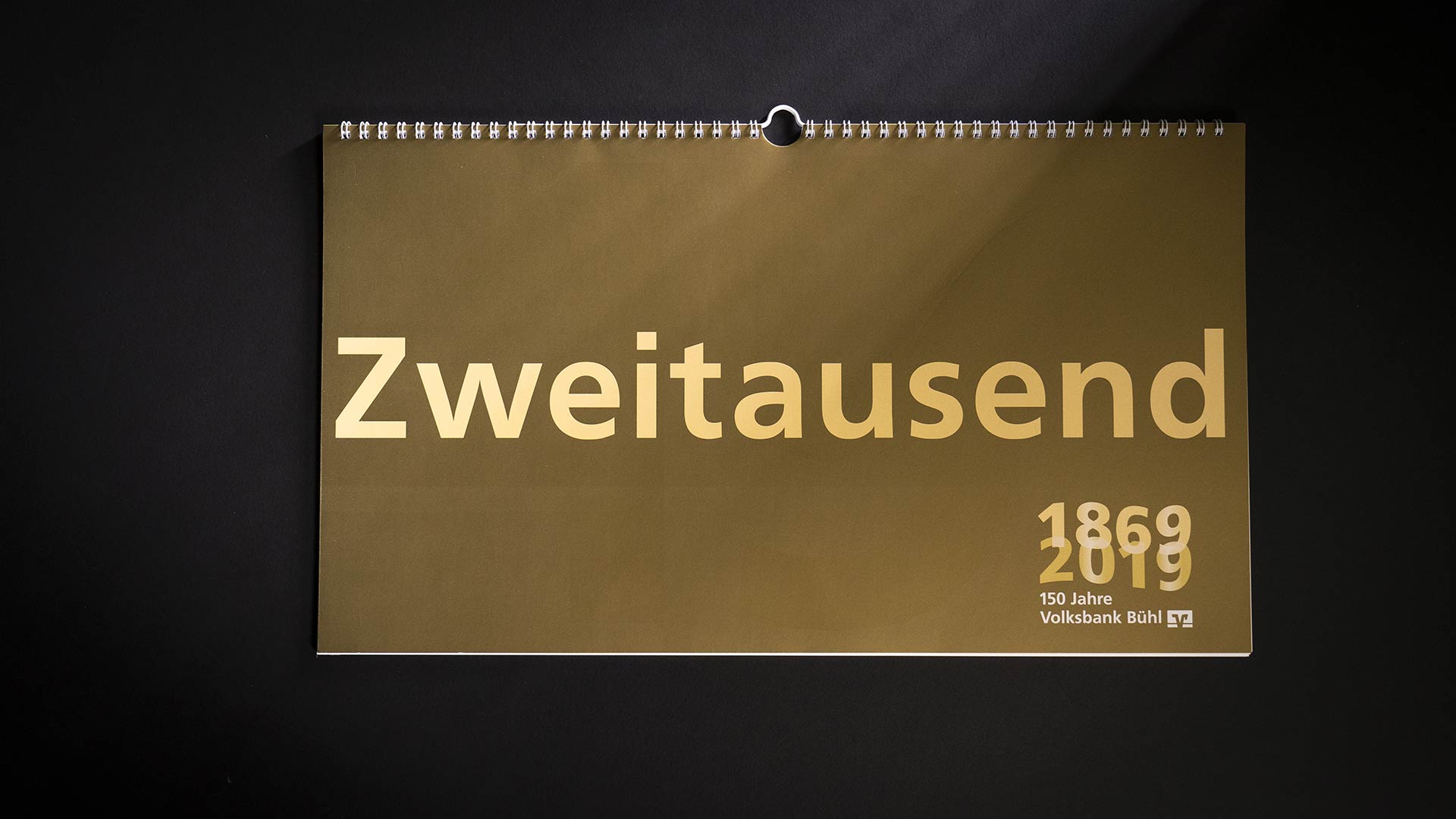

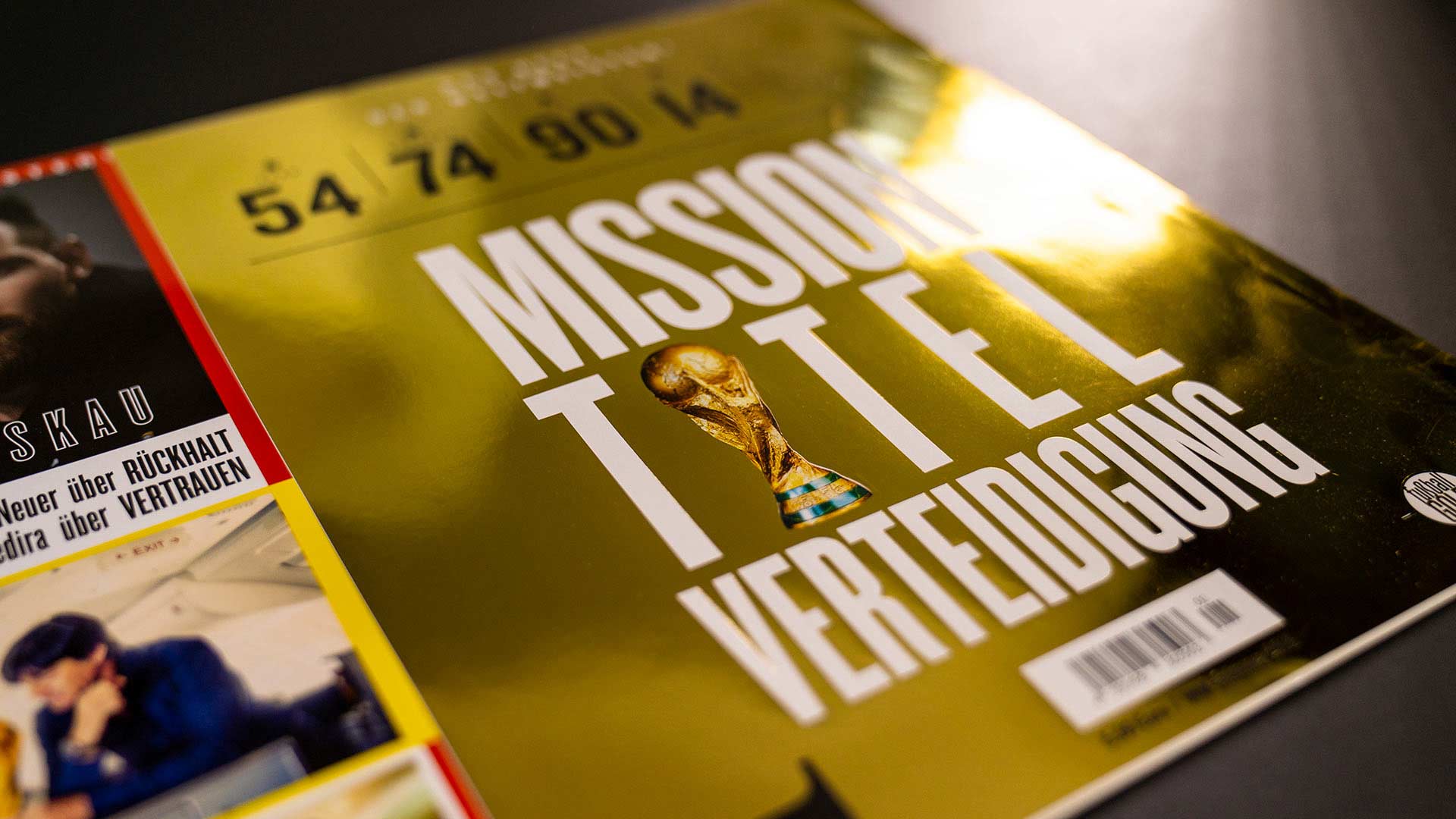

Print finishing with metallic colours: This is how printed items becoming ornamental pieces

Silver, gold, brass or iridescent metallic, metallic printing inks increase the value and are able to represent jewellery as well as machines or vehicle components in a way that closely resembles reality.

A piece of advice from B&K’s finishing specialists: Prints that are printed with metallic colours are very prone to scratching and should, therefore, be coated with a protective varnish. Varnish finishings containing metallic pigments achieve a higher gloss.

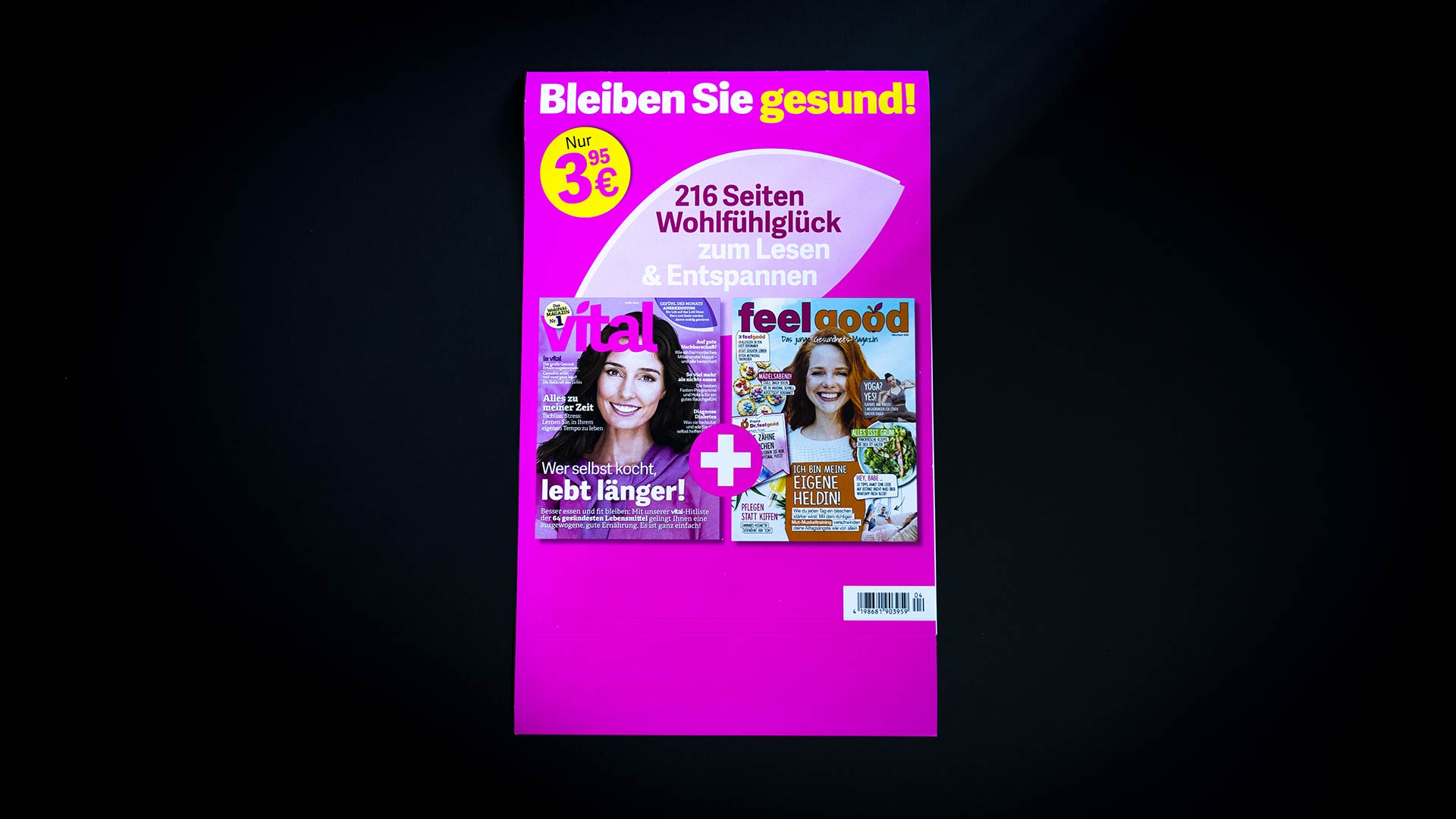

Fluorescent colours: You may wish to rely on a strong signal effect.

Fluorescent colours, also known as luminescent inks, ensure a high degree of attention and are frequently utilised to highlight notes and special offers.

A piece of advice from B&K’s finishing specialists: The signal effect of the fluorescent colours depends upon the application of paint.

Products with this finishing

Inline finishings

OFFSET PRINTING – WITH LACQUERS

Printing lacquers based on oil or water

Printing lacquers based on oil and dispersion coating (also known as water lacquers) also serve as a primer or functional lacquer, e.g. in order to protect printed matter from yellowing or to increase its resistance to scratches and its abrasion-resistance. Dispersion coatings may be enriched with pearlescent, metallic or scented pigments. Finishings covering either a partial surface or the entire surface, and in the varieties of matt, gloss and soft touch (dispersion coating) are available.

A piece of advice from B&K’s finishing specialists: Matt oil print coating combined with drip-off varnish (dispersion coating) or UV varnish (hybrid finishing) ensures eye-catching gloss contrast effects.

UV varnish: The all-rounder among the inline finishing lacquers

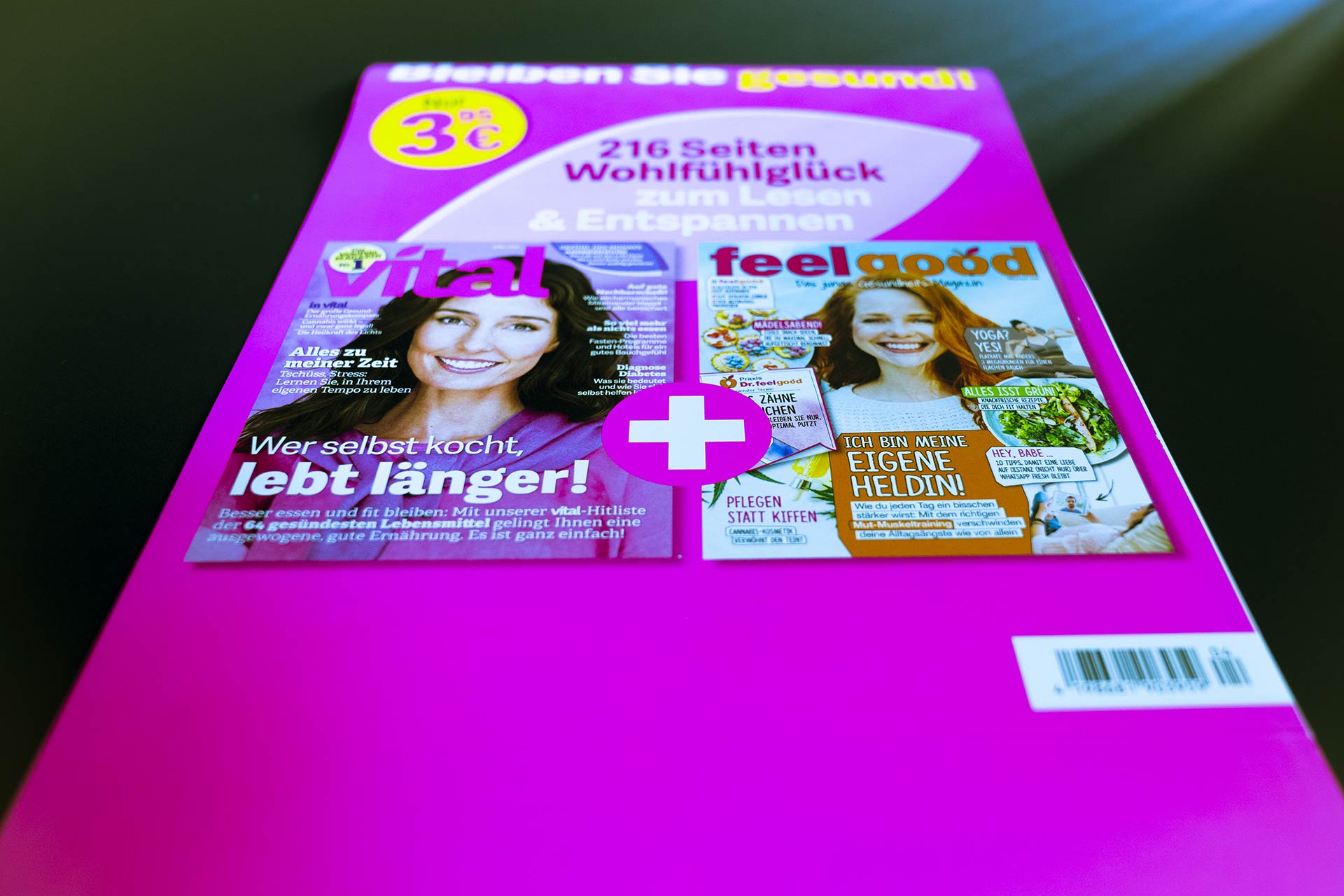

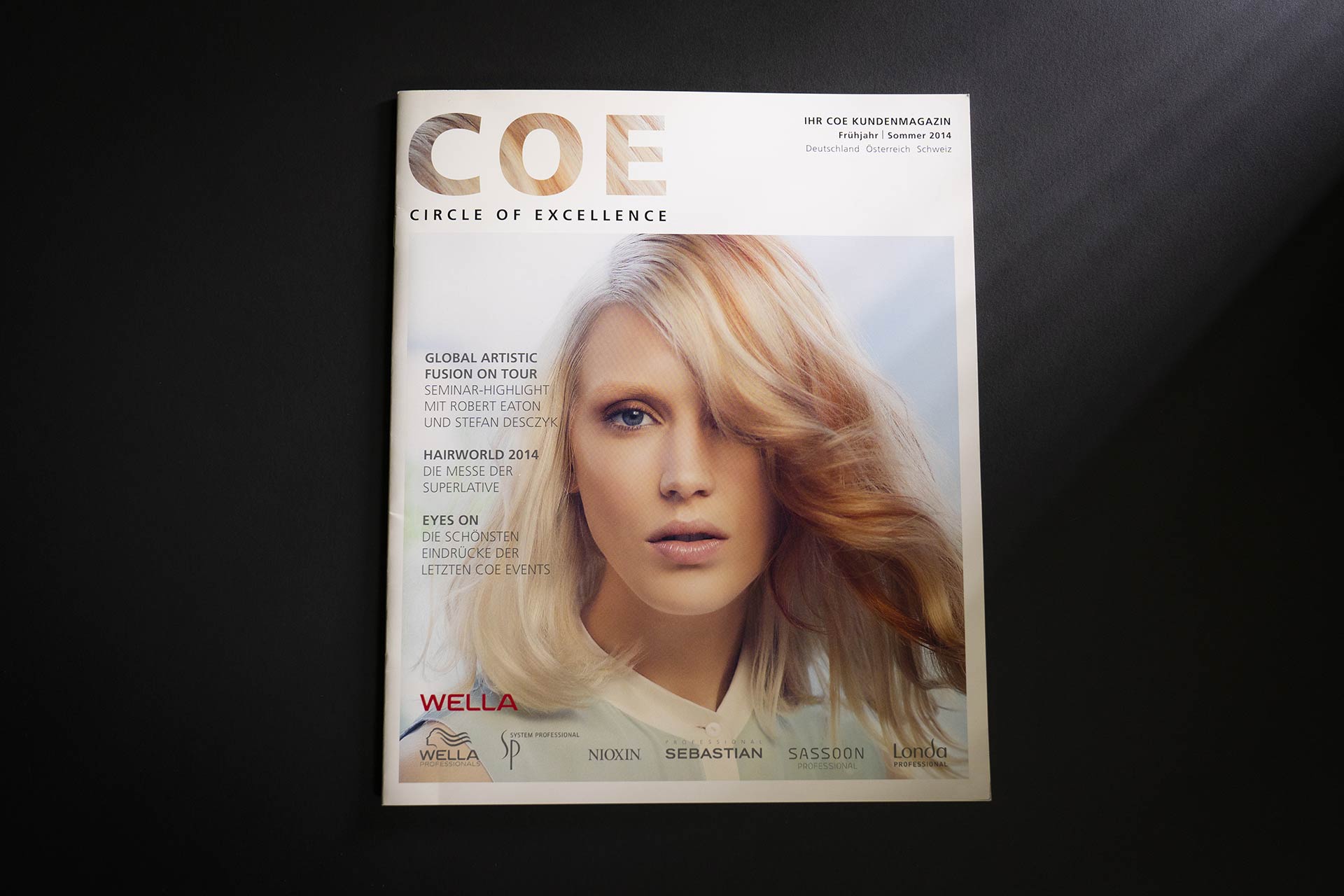

Print finishings with UV varnish, partially applied, over the entire surface or in spots, make for one-of-a-kind effects with magazine envelopes, ad specials or annual reports. UV varnishes have a high degree of appeal and are very well suited for achieving a spatial effect or emphasising structures.

A piece of advice from B&K’s finishing specialists: UV varnishes can also be applied on both sides and they are extremely abrasion-resistant and scratch-proof.

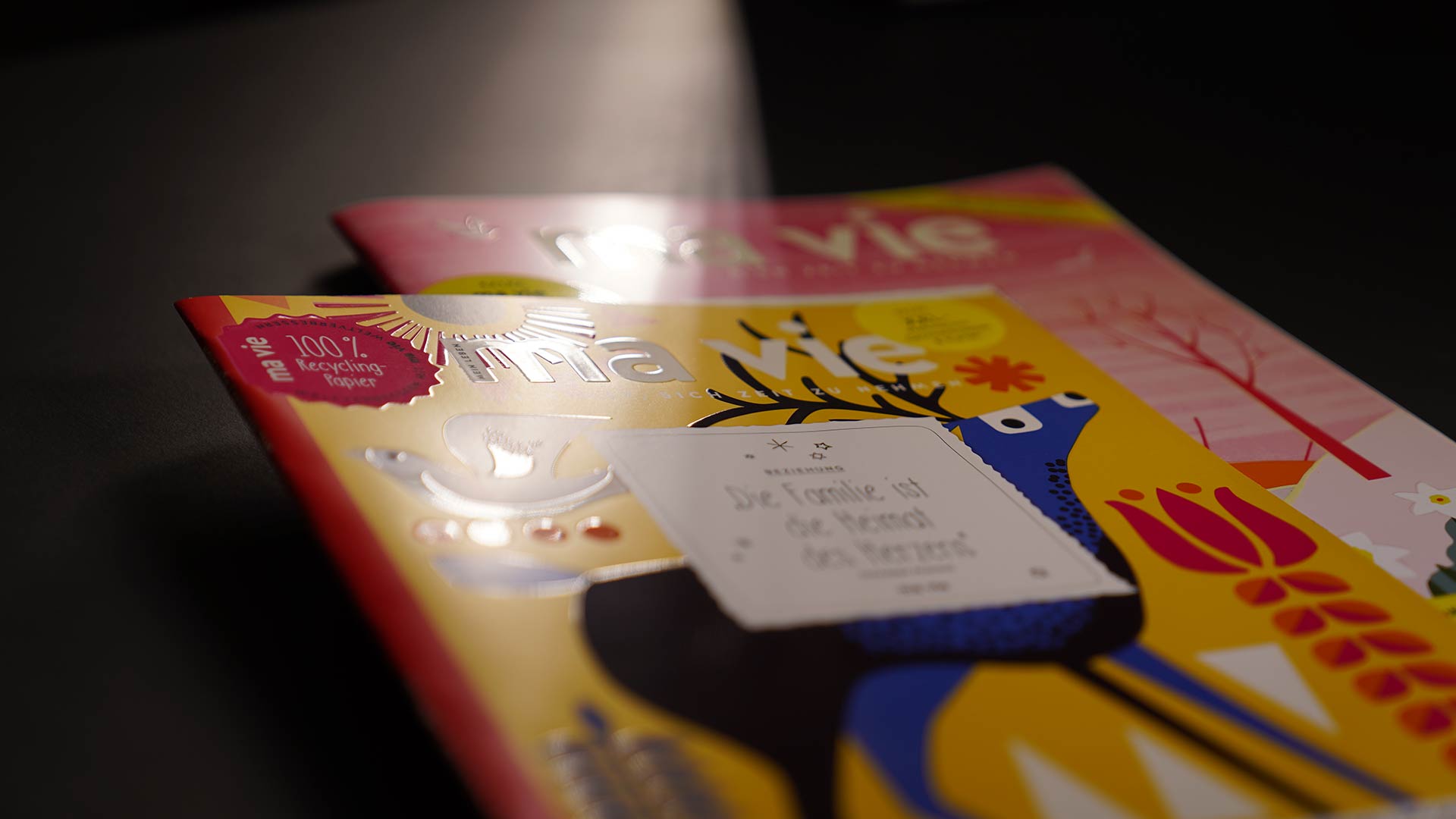

Soft-touch varnish: Silky effects, almost like a second skin!

Palm stones: Envelopes, magazines, brochures or even invitations that are finished with soft-touch varnish, captivate the recipient with the excellent haptic effect. Due to their smooth, velvety feel, almost similar to human skin, the surfaces effectively become “palm stones”.

A piece of advice from B&K’s finishing specialists: Soft-touch varnishes are very well suited for coated and smooth papers as well as non-absorbent surfaces, such as foils and laminations. Surfaces finished with soft-touch varnish are very easily scratched.

Iriodin coating: This provides for a grand panoramic view due to the finest glimmer effects, pearlescence or shimmering light reflections

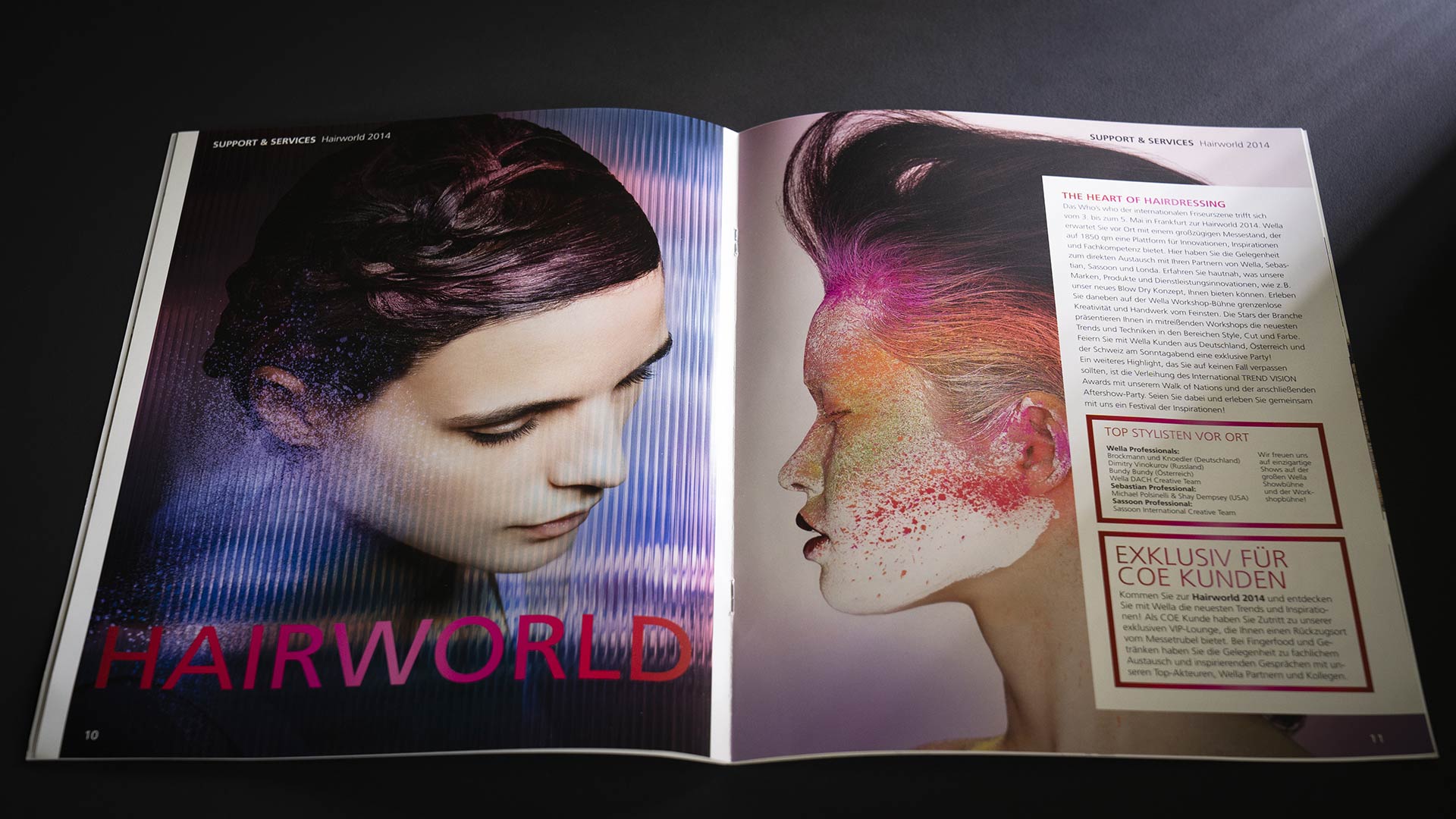

Prints finished with iriodin coating ensure elegant, splendid impressions and a real phenomenal effect. This finishing is also especially suited for high quality brochures, magazines, covers or exclusive customer dialogue solutions.

A piece of advice from B&K’s finishing specialists: Ioridin coating finishings are particularly effective on very smooth surfaces and dark substrates.

UV hybrid varnish: Dazzling and robust at once

With the combination of print varnish and UV varnish – applied partially or over the entire surface – envelopes of annual reports, catalogues or presentation portfolios, for example, can be brilliantly highlighted. At the same time, the prints coated with this finishing process are scratch-free and abrasion-resistant.

A piece of advice from B&K’s finishing specialists: Impressive matt/gloss or pearlescent effects can be achieved using this procedure.

Drip-off varnish: Richly contrasting matt/gloss elegance

Drip-off varnishes likewise rank among the hybrid processes. They make for thrilling contrasts between matt and gloss surfaces. Lettering, lines or logos, in image brochures or annual reports for example, can be emphasised exclusively and tangibly using the drip-off method. Applied to the entire surface, printed matter that is refined in such a way develops an elegant, high quality character.

Scented varnish creates refined experiences for (almost) all the senses

We aim to achieve surprising, scented experiences with a multisensory effect using scented varnish finishings. Mailshots, postcards or coupons are in that way transformed into effective and high quality advertising media. Scented varnishes can be applied to the entire surface, to part of a surface or in the form of a motif. The minimum format of the rubbing surface should be 5 cm x 5 cm.

A piece of advice from B&K’s finishing specialists: Besides finishing using the inline finishing process with scented varnishes, we can refine the products with scented glues (using the screen printing procedure).

Products with this finishing

OFFLINE FINISHINGS

WITH SCREEN PRINTING RESISTS

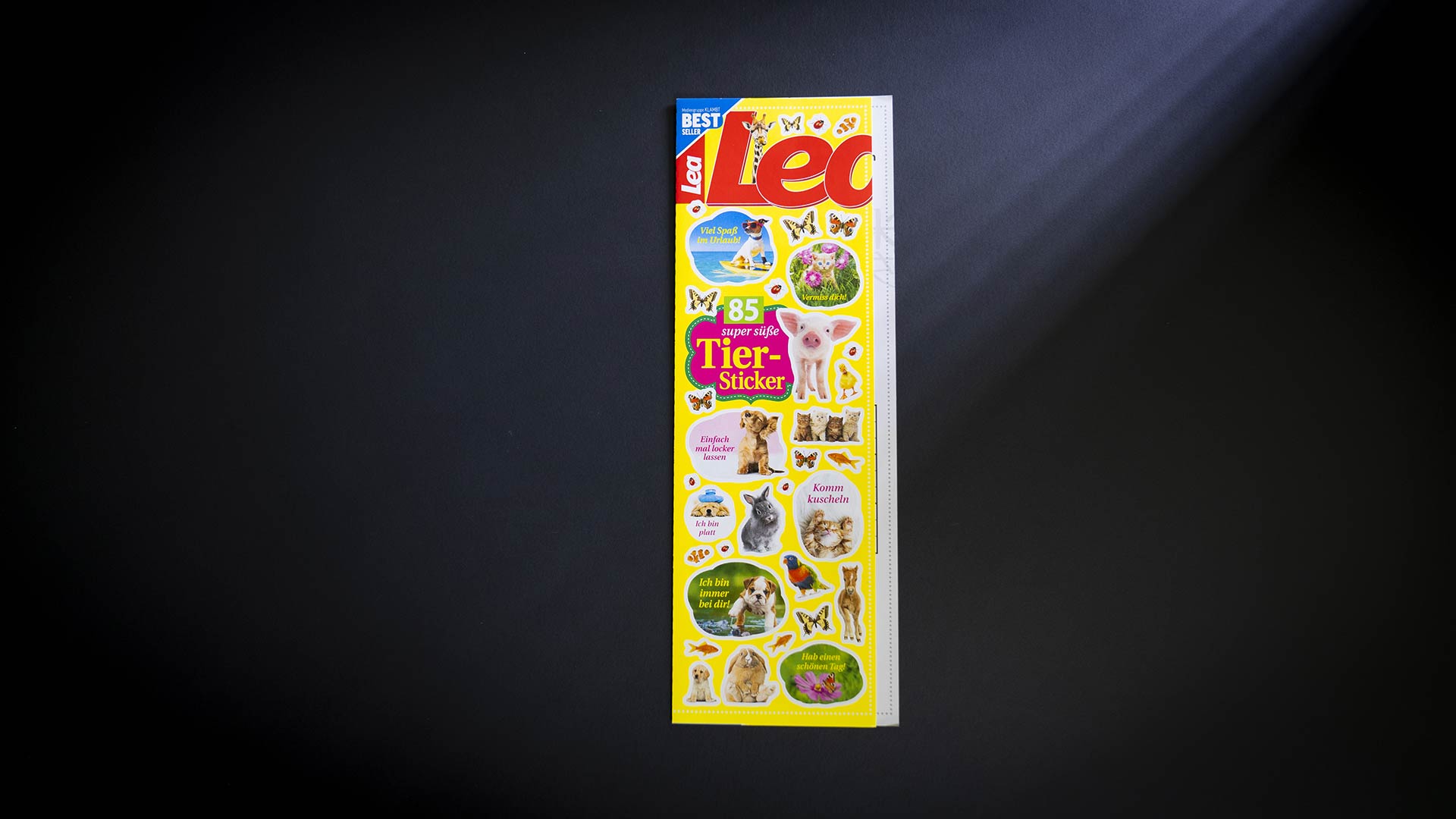

Glitter lacquer: Get sparkling!

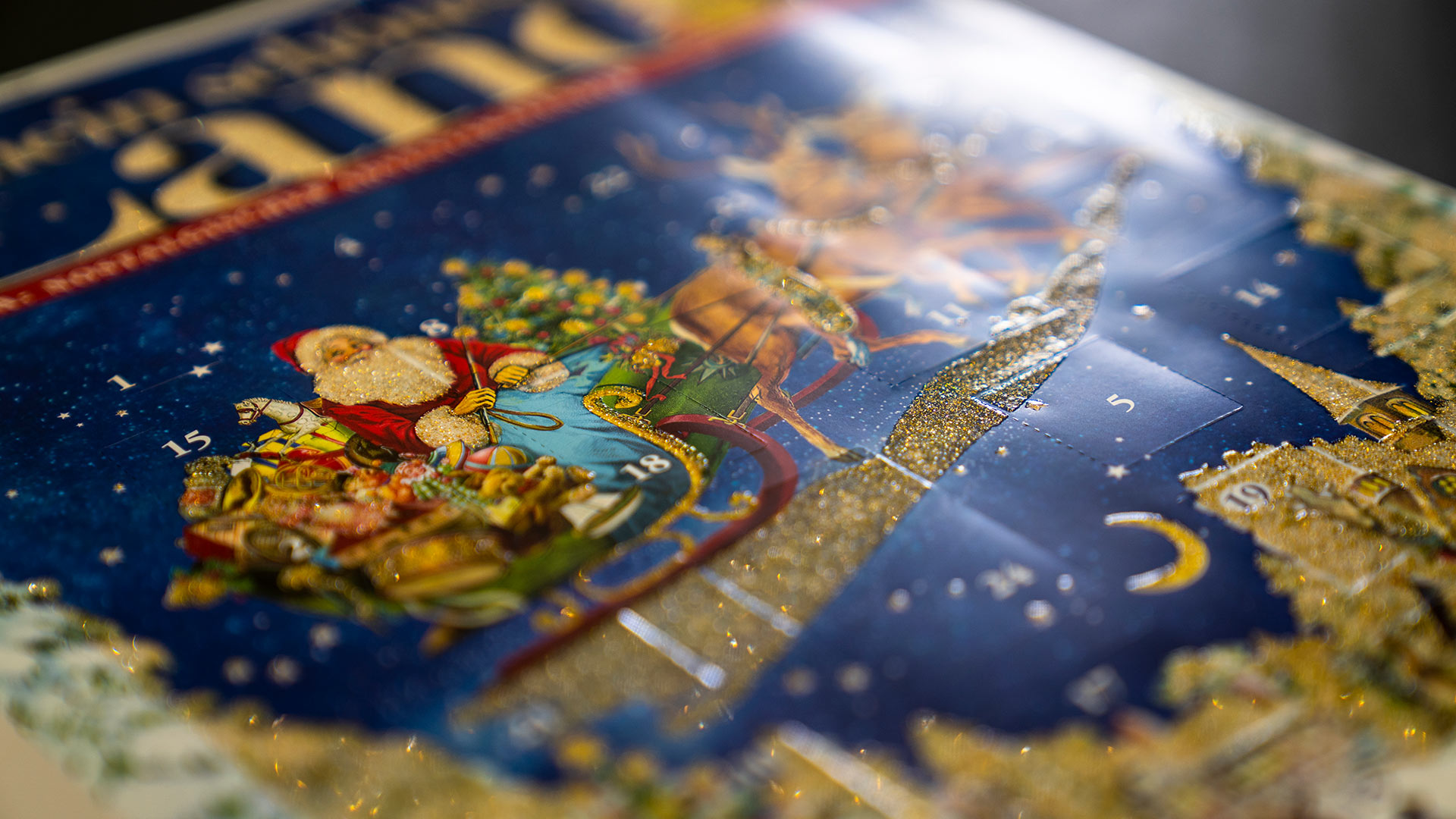

The finishing with glitter lacquers makes for silvery, golden or multicoloured glittering effects, and leaves a fine, durable impression. This type of offline finishing using the screen printing technique gives kids’ entertainment products, sheets of stickers, magazine covers, Christmas cards or advent calendars a glamorous appearance.

A piece of advice from B&K’s finishing specialists: Glitter lacquers may be based on motifs and can cover the entire surface or just a part of it. Laminated products may also be refined with glitter lacquer.

Relief varnish: A three-dimensional effect without the material becoming deformed

It is not for nothing that relief varnish is also called “water drop varnish” or “pseudo-embossed varnish”, for precisely those are the effects or benefits which can be achieved with this form of refinement. Spatial effect is thus just as possible as the noticeable outlining of lettering and motifs – without deforming the material.

A piece of advice from B&K’s finishing specialists: Ideal for finishing materials that cannot be embossed as well as for displaying information in Braille.

Varnish for scratches: Perfectly concealed!

Tension comes into play here: With varnish for rubs or scratches, we make everything that is not supposed to be discovered at first glance, such as pictures, lottery codes, sensitive information, etc., invisible.

This finishing, carried out in the screen printing process, which can be deployed for either entire or partial surfaces, is perfectly suited for kids’ entertainment products, “scratch books”, raffles tickets, mailshots or prize draws.

A piece of advice from B&K’s finishing specialists: The original grey gloss paint can be overprinted in any colours desired.

Textured finish: It feels deceptively real!

The effect of a genuine wood, sand or stone surface is the highlight with this form of refinement. The visual and haptic effects are most impressive, and allow for representations that are very close to reality and true to nature, such as in the case of books of samples, catalogues, mailshots, ad specials, etc.

A piece of advice from B&K’s finishing specialists: The finished print image is scratch-free and abrasion-resistant. Prints finished over the entire surface are also moisture-resistant.

Remoistenable glue: Perfect for response elements, self-mailers or sheets of coupons

Simple closure and cost-effective shipping are most certainly the main benefits when making use of remoistenable glue. This form of finishing is variable, e.g. in the form of a strip, point or V-shape.

A piece of advice from B&K’s finishing specialists: This would be a good and cost-effective choice for response elements of customer dialogue solutions, as separate answer elements are dispensed with.

Phosphorescent colours: Printed matter which only lights up in the dark!

By daylight invisible, with phosphorescent colour varnishes printed matter develops its full effect in the dark, and makes for surprising effects with flyers, brochures, kids’ entertainment products, signposts and on envelopes.

Products with this finishing

FOIL FINISHINGS

Foil lamination: Durability and neat presentation through a finishing process

Depending upon the type of foil - shiny foil, matt foil, structured foil, soft-touch foil – with lamination we achieve an extremely effective surface effect, such as colour depth and a high degree of brilliance, compelling haptics or a pleasant feel. For that purpose, the prints, printed with a design, are coated with a wafer thin protective or decorative foil (also known as cellophane coating), which also protects the printed matter from dust, dirt and moisture.

Hot foil embossing: This is how impressive 3D effects are created

This form of thermal finishing is perfectly suited for emphasising lettering, lines and ornaments as well as spot-lacquered motifs, in a haptically effective and three-dimensional way.

Hot foil embossing, also known as thermal lamination, with high quality magazine covers, annual reports and portfolios as well as with deeds, coupons and congratulatory cards, entrance tickets or business cards.

A piece of advice from B&K’s finishing specialists: The material to be laminated needs to have a minimum degree of heat resistance.